- Home

- Manufacturing

- Compound Machining Business

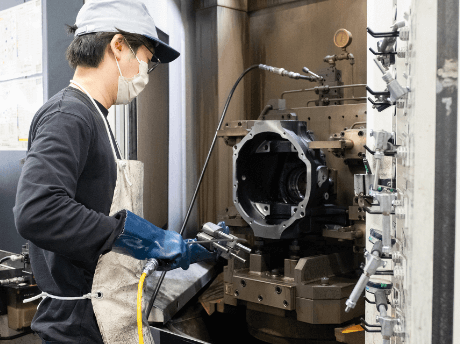

Compound Machining Business

We machine an array of materials, including aluminum alloy, iron, and cast metal, as well as parts with complex shapes at high speed and precision.

Business

Machining of suspension parts for forklifts

Compound machining business workflow

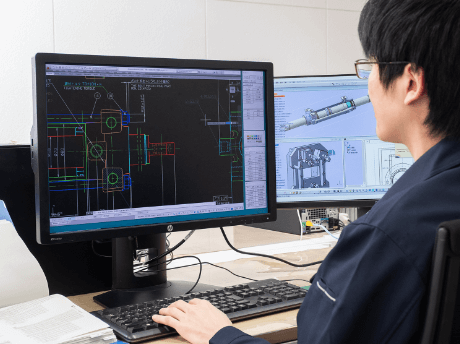

Use of 3D CAD data

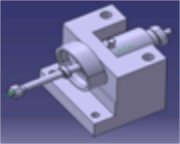

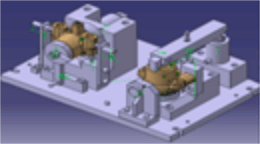

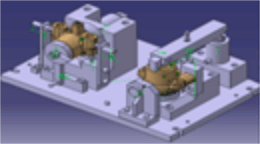

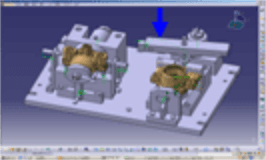

Use of 3D jig parts to streamline production equipment

We work to shorten production preparation times by studying jigs, tools, and cutting tools in advance in a way that effectively utilizes 3D CAD data.

| Creating 3D models of jigs | Checking for interference | |

|---|---|---|

| Jig design |

Creating 3D jig parts  Assembling jig parts and positioning workpieces |

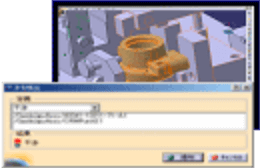

Switching workpieces to check for interference |

| CAD operations |

Creating a library of jig parts  Assembling jigs so that movable parts can be operated |

Using a design table to modify interference locations |

| Creating 3D models of jigs | |

|---|---|

| Jig design |

Creating 3D jig parts  Assembling jig parts and positioning workpieces |

| Checking for interference | |

Assembling jig parts and positioning workpieces |

|

| Creating 3D models of jigs | |

| CAD operations |

Checking for interference  Assembling jigs so that movable parts can be operated |

| Checking for interference | |

Using a design table to modify interference locations |

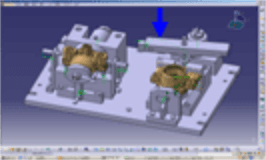

Machining

Creating multifaceted machine groups that can accommodate high-speed, high-precision machining

◎We operate a variety of machines, including high-speed machining centers and NC combined lathes, which can machine high-precision parts at high speed, as well as honing machines and cylindrical grinding machines to ensure we can meet the full array of customer machining needs.

◎ We manufacture aluminum alloy, iron, and cast metal parts with complex shapes, from multi-model, small-lot runs to mass production.

Inspections

Using an extensive range of measuring instruments to inspect parts

We assure product quality by carrying out daily inspections, shipping inspections, sampling inspections, and other testing using state-of-the-art instruments, including rigorously managed measuring instruments, liquid particle measuring machines, and 3D measuring machines.

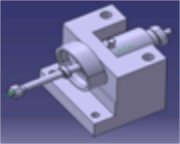

Example parts

Suspension parts for forklifts

Machined parts found in forklift suspensions

Machined parts from Handa are hard at work keeping forklifts running safely.