- Home

- Manufacturing

- Welding and Joining Business

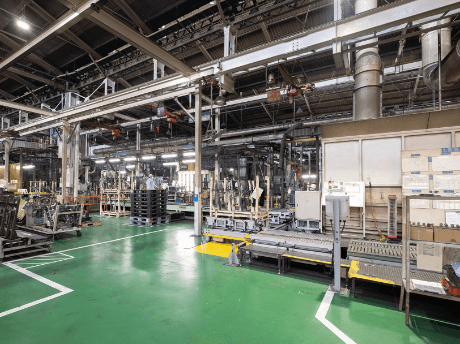

Welding and Joining Business

We take advantage of refined welding technology and state-of-the-art factory automation systems to manufacture a range of cargo handling parts for forklifts.

Business

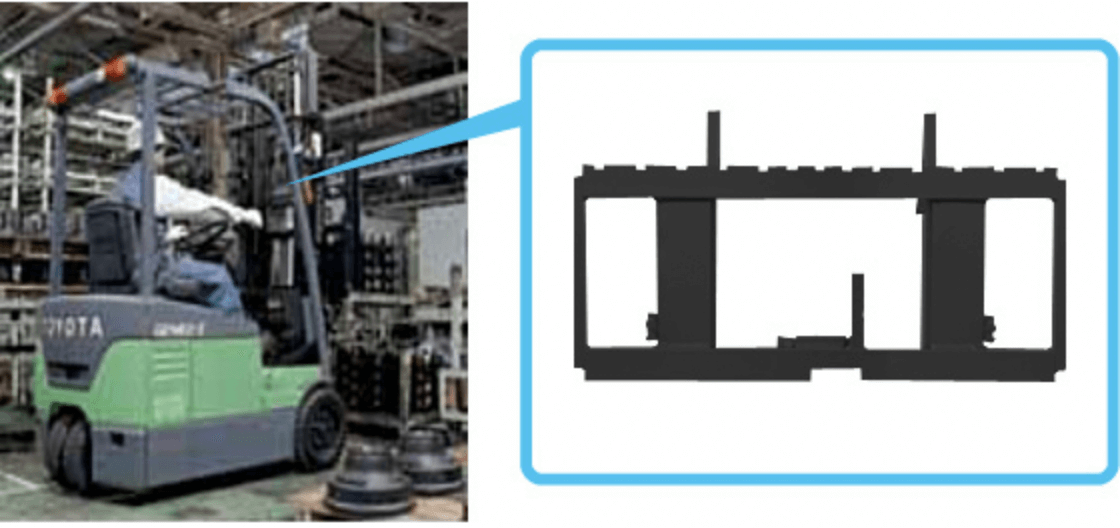

Machining, welding, and painting of cargo handling parts for forklifts

Welding and joining business workflow

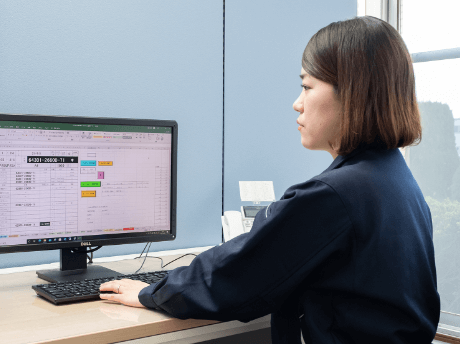

Order receipt and production instructions

Using IT to implement just-in-time sequential production

We collect information in a timely manner via electronic interactions with customers and use a database to level and prioritize it. Then we issue production instructions for individual processes to implement just-in-time sequential production, an approach that lets us manufacture the necessary quantity of products as they are needed.

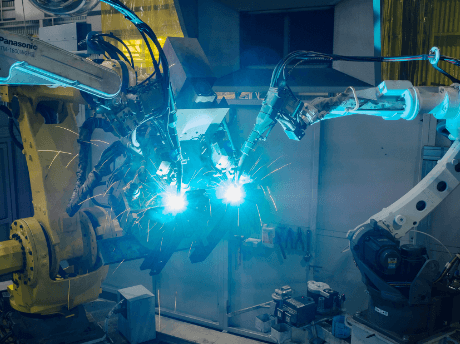

Machining and welding

Using factory automation technology to improve productivity

We use servo jigs to instantly and accurately determine the dimensions of products with different shapes one at a time. Welding robots that interoperate with the servo jigs ensure stable weld quality and production speed, allowing us to implement low-cost, sequential production of one product at a time while reducing lead times.

Painting

Applying environmentally friendly powder coatings

Since powder coatings are solvent-free, they don’t produce pollution due to solvent volatilization, and hazards arising from the toxicity and flammability of organic solvents can be avoided. Additionally, use of automation increases productivity.

Shipment

Example of cargo-handling parts (welded parts) for forklifts

Attachments

Attachments from Handa help streamline forklift cargo-handling work.