- Home

- Manufacturing

- Combining Worker Skills and Automation

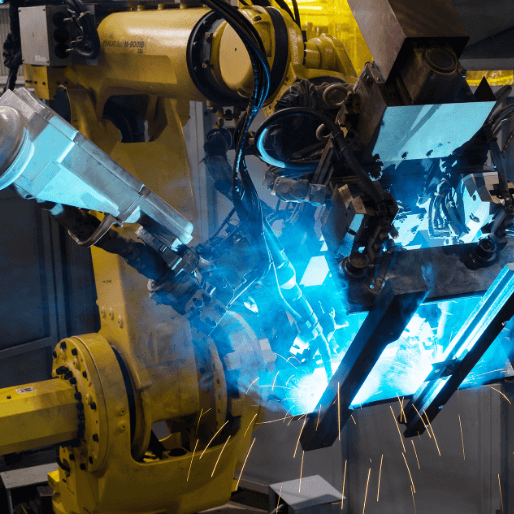

Combining Worker Skills and Automation

Creating next-generation manufacturing by combining skills polished through experience with automation using state-of-the-art technology

With the mechanisms of manufacturing undergoing major change, we’ve forged a new approach to manufacturing through trial and error so that we can satisfy a variety of customer wishes by automating engineers’ expertise using information and communication technologies (ICT) and the Internet of Things (IoT) while taking advantage of manual skills for high-precision machining that is difficult to accomplish through automation. This approach makes possible high-quality production with fast lead times, even when manufacturing a large number of products in small quantities.

We emphasize human resources development because we believe that manufacturing starts with character-building and that job quality starts with people. Going forward, we will continue to create next-generation manufacturing that combines skills and automation.

▲ Compound jigless automated welding robot

▲ Highly skilled welders

▲ Highly skilled lathe operators